Inside the Process: How CNC Laser Cutting Brings Precision Projects to Life

At Tri-State Metals, precision isn't just a promise — it's the foundation of everything we do. One of the standout tools in our fabrication arsenal is our CNC Laser Cutting Machine, renowned for delivering clean, consistent, and highly accurate results. But what does it take to go from a customer's concept to a perfectly cut metal part? Here's a look behind the scenes at the full CNC laser cutting process — from digital file to final product.

1. Project Kickoff: From Concept to CAD File

Every CNC laser cutting job begins with design and planning. Whether a customer supplies their own CAD files or works with our in-house team to develop them, this first step is critical.

We work with CAD (Computer-Aided Design) software to create detailed 2D profiles of the part to be cut. These digital drawings define every curve, corner, and cutout. For more complex parts, we ensure designs are optimized for laser cutting — removing unnecessary geometry, simplifying intersections, and confirming material compatibility.

✔️ Precision starts here — because a perfect cut begins with a perfect file.

2. Converting to Machine Code: CAM & Nesting

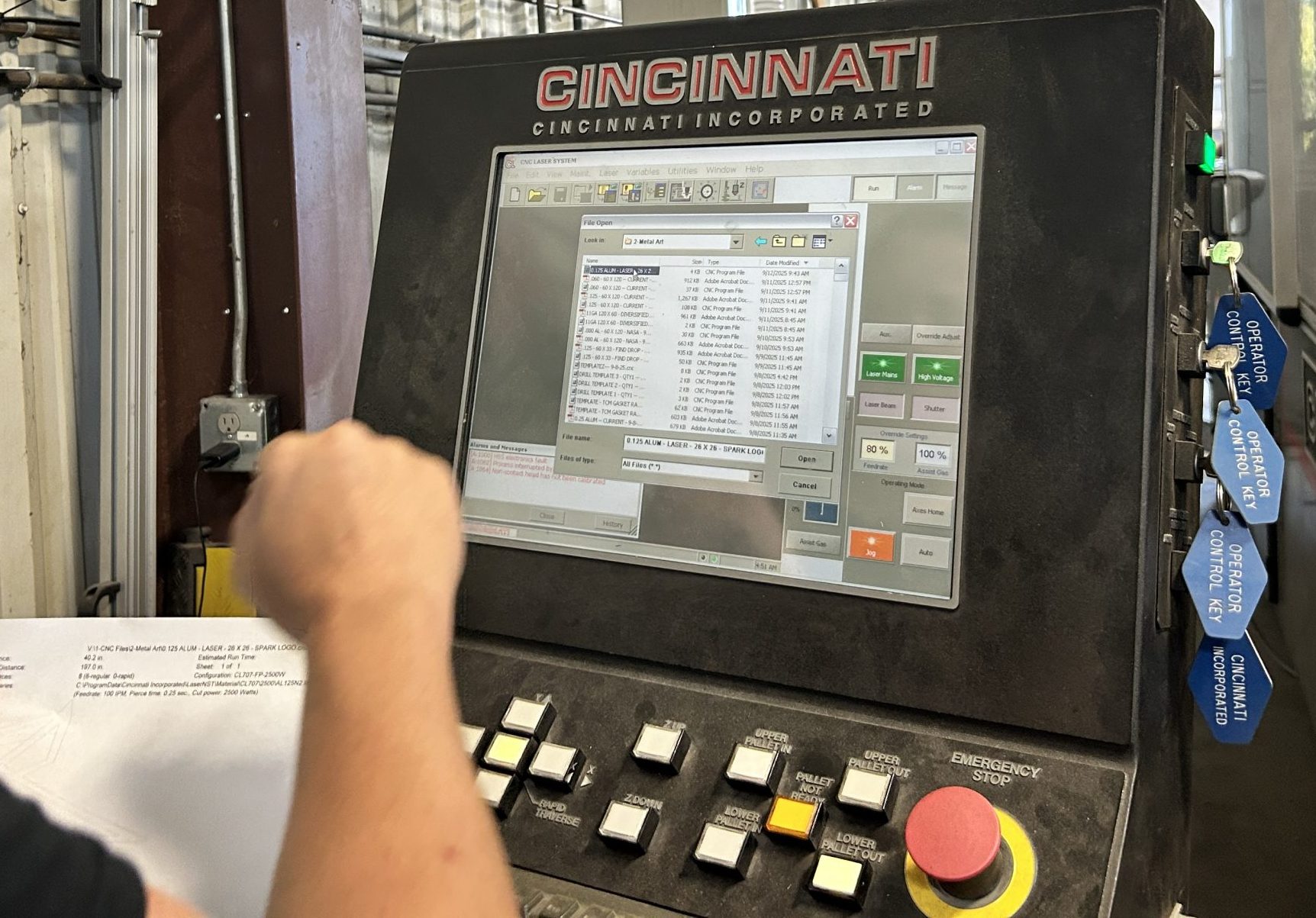

Once the CAD drawing is finalized, it moves into CAM (Computer-Aided Manufacturing) software. This software translates the drawing into a language the CNC laser cutter understands — called G-code or machine code.

Here’s what happens in this step:

- Toolpath Generation: The software plots the most efficient cutting path for the laser, minimizing heat zones and reducing cut time.

- Nesting: To reduce material waste and lower production costs, parts are strategically nested — like puzzle pieces — on the sheet material.

- Cut Parameters: We set parameters such as laser power, cutting speed, assist gas selection, and pierce delays based on the material type and thickness.

3. Material Prep & Machine Setup

Before cutting begins, we prep the material. Whether it’s carbon steel, stainless, or aluminum, our team ensures the correct grade and thickness is loaded onto the laser bed.

Then, our skilled technicians prepare the machine:

- Laser Head Calibration: Ensuring the beam is properly focused and aligned.

- Assist Gas Setup: Gases like oxygen or nitrogen are selected to improve cut quality and edge finish.

- Fixture Checks: For repeat parts or critical tolerances, custom fixturing may be used to keep sheet metal stable and flat.

Safety protocols and equipment checks are completed to ensure the laser is operating at peak performance.

4. Cutting in Action: High-Powered Precision

With the machine fully programmed and set up, it’s time for the laser to go to work.

The CNC laser cutting machine uses a high-intensity beam of light to melt or vaporize metal at pinpoint locations. Driven by the G-code, the laser follows its programmed path, executing each cut with accuracy.

Here’s what makes laser cutting so powerful:

- Edge Quality: Clean edges often require little post-processing.

- Detail: Capable of handling intricate geometries, fine features, and tight tolerances.

The entire cutting process is monitored and adjusted in real time, ensuring every part meets our exacting standards.

5. Final QC & Post-Cut Processing

Once cutting is complete, parts are carefully removed from the bed and go through quality control. Our team inspects for:

- Dimensional accuracy

- Edge quality

- Material integrity

- Cleanliness of cuts

Depending on the job, parts may be deburred, cleaned, or passed along to other fabrication steps such as bending, welding, or finishing.

Why It Matters: Faster Turnarounds, Higher Quality, Lower Waste

Our CNC laser cutting process is designed with efficiency, precision, and repeatability in mind. By tightly controlling every stage — from digital file creation to the final cut — we’re able to offer:

- Shorter lead times

- Minimal material waste

- High repeatability across large production runs

- Custom solutions tailored to your project

Whether you're producing one prototype or thousands of components, Tri-State Metals delivers parts that meet tight tolerances and exceed expectations.

Have a Project in Mind?

Our team is ready to help you bring it to life with expert laser cutting services. Reach out today to learn more about our capabilities or to request a quote.

Call us at 256-760-0006 or contact us online to get started.